Lower part costs. Higher precision.

No trade-offs.

Our processing technology combines the best of CNC and MIM

in one efficient process.

Reduce Unit Costs with Cutting-Edge Manufacturing

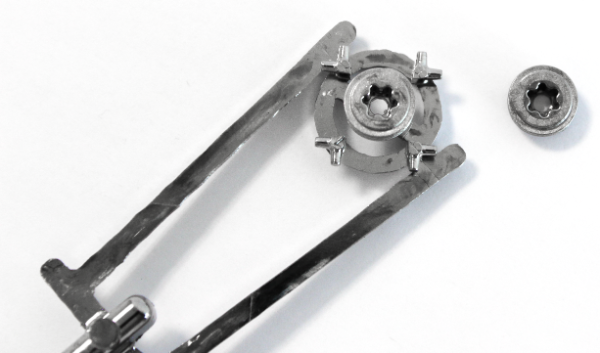

Due to a significantly reduced cycle time unsing our injection molding process, unit costs were reduced by over 50%. These results were achieved by a leading OEM in the medical instrument sector. The component concerned is a CNC-machined stainless steel part with internal thread, which has an annual production volume of 10.000 pieces:

- Weight: < 10 g

- Wall thickness: 1 - 2 mm

- Tolerances: < ± 10 µm

.png)

| Status Quo: CNC processing of stainless steel | Our Solution: Injection Molding of amorphous alloys | |

|---|---|---|

| Tooling invest | 1.000 € | 35.000 € |

| Cycle time per part | 10 min | 2 min |

| Material per part | 0.20 € | 1.00 € |

| Processing per min | 2.00 € | 1.50 € |

| Cost per part | 20.75 € | 8.75 € |

Maximum precision for complex metal components

- Wall thickness: 100 µm - 5 mm

- Tight tolerances: ± 5 µm, low shrinkage (< 0.5 %)

- Length tolerances: ± 0.003 - 0.01 mm

(5 x better than with MIM process: ± 0.02 - 0.05 mm) - Surface roughness: 0.05 µm

(20 x better than with MIM process: 1.00 µm3) - Precision of the components: 3 - 10 µm

(10 x better than with MIM process: 20 - 50 µm) - High gloss surface, removal of parting lines by tumbling possible

- Injection of internal structures possible

.1218711949754481985.png)